The Issue on

Rotation and Safety of the Balancing Drum of movable beam lifting system of the

Gantry-type Bucket Wheel Stacker & Reclaimer

(Abstract)

(Classic)

Yimin Li Bulk-Onweb March 30, 2017

Keywords:

Gantry-type bucket wheel stacker reclaimer; lifting system; wire rope reel;

balance; balance wheel balance wheel to rotate;Balance

drum; Gantry; Bucket wheel stacker & reclaimer;

Overview

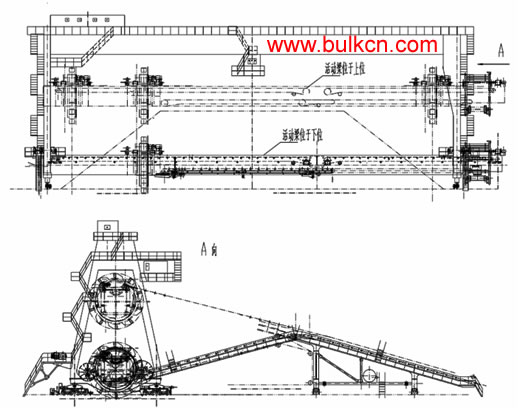

The gantry-type bucket wheel stacker & reclaimer have been used in domestic

nearly half a century. It is estimated that nearly a hundred of gantry-type

bucket wheel stacker & reclaimer and similar equipments have been designed and

manufactured in China. Which are mainly used in thermal power plants, and most

of them are still in service. The key feature of gantry-bucket wheel stacker and

reclaimer is its lower part contains a movable beam which consists of bucket

wheel, bucket wheel trolley and belt conveyors. The beam is driven up and down

using pulley blocks by hoist. The basic design method of the movable beam hoist

system for equipments of this kind are the same. It appeared that many serious

accidents happened domestically caused by movable fallen down due to steel wire

rope worn and broken. The accidents affect the users’ production schedule, and

lead to significant economic loss.

gantry-type

bucket wheel stacker reclaimer

1. Movable beam

and the lifting mechanism

The movable beam of gantry-type bucket wheel stacker & reclaimer acts as the

important steel structure which supports the conveyor, bucket wheel device and

bucket wheel trolley. The movable beam consists of two pieces of I-shaped beams.

There are angle steels and channel steels connect between the two. Usually,

there are three belt conveyors installed in the middle of movable beam. Tracks

for bucket wheel trolley travelling lay on the upper part of the two I-shaped

beams. Fixed pulleys used to drive and adjust the lifting height of movable beam

are arranged on both ends of the beam.

lifting mechanism

The lifting mechanism of movable beam for gantry-type bucket wheel stacker &

reclaimer are mostly driven using pulley blocks by steel wire rope hoisting

mechanism. So far, the principles of wind the wire rope of pulley blocks for

most equipment domestically are almost in the same. The differences between them

in detail are the ratio of pulley blocks. The ratio of pulley blocks for lifting

mechanism is designed in 8 times or 6 times as usual.

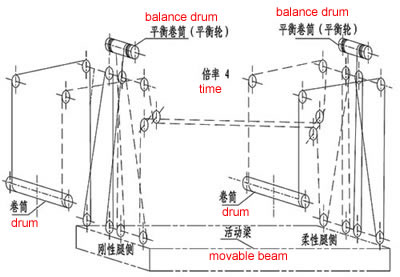

The lifting system of movable beam for gantry-type bucket wheel stacker &

reclaimer is the four ropes system which driven by dual drums. Each sheave is

pull by two wire ropes wound on drive pulley respectively between the lifting

side and opposite side of the movable beam. These steel ropes are finally

gathering and fixed on the balance drum (the balance wheel). Steel rope end

fixed on the drum should be wound at least 3 safety cycles, which ensure that

there is enough friction that the rope cannot be drawn from the rope clamp. The

four-rope lifting system of movable includes 8 ropes. Four ropes of which are

fixed on the drum, and the other fixed on the balancing drum. There are two

purposes of the original design for the lifting system. One purpose is that

protect the equipment as dual fail-safe, which means if one rope broken the

other can protect the movable beam not to fall down. The dual fail-safe make

sense at the precondition of rotational angle of balance drum is not too big and

there is enough braking power if one rope broken. The other purpose is that

ensure that both ends of movable beam keep horizontal and synchronically during

lifting.

At present, the basic principle of wire rope hoist lifting system for movable

beam of gantry-type bucket wheel stacker & reclaimer in domestic is almost the

same. The differences of lifting system for movable beam as following: the power

of driving motor on hoist, the ratio of pulley block of lifting system and the

form of balancing devices using to balance the forces between the two ropes(most

of devices use balance drum, and the others adopt balance beam).

2. Reasons of big rotational angle of balance drum for movable beam lifting

system

Balance drum on movable beam system (balance wheel) is used to balance the

forces between the two ropes, and automatically adjust the small difference of

ropes length on two sides. The balance drum act as protection device is designed

to dual ropes system. If one side of balance drum’ steel rope is broken, the

balance drum will be blocked after rotating a small angle. Which means if one of

the steel ropes was broken and fall, the other will still been wound on the

balance drum and pull the movable beam. But too big rotational angle of balance

drum is not acceptable for the equipment in normal working condition. The

reasons of big rotational angle of balance drum are:

The value of forces at lifting points on the two sides of movable beam are

inequality(F1≠F2), including the frictional resistance forces of pulley and

elasticity factors of ropes, will cause the small difference of the forces on

the two drive drums. And it will lead to the difference of rotational angles of

drive drums, so as to cause the balance drum rotation.

2) Difference of the frictional resistances, different performances of motors

and different braking moments of brake will cause the difference of rotating

speeds of start-up and braking, which result in the balance drum rotate at a

certain angle.

3) When the bottom of movable beam or bucket wheel fall on stockpile or ground,

the force at the support position will cause the changes of tensile forces on

both ends of movable beam. The movable beam will be held in this situation that

cannot be lay down. It is possible that hoist wire ropes at one or both side are

relaxation or even accumulated at the drum, which is commonly known as ’wire

ropes disorder’. At that time, the balance drum will inevitably rotate. This

phenomenon will lead to grave consequences, especially when the movable beam

touch to the ground or lay onto stockpile for a long time. As the movable beam

has been move up and down, more ropes will accumulate on the drum, the steel

rope will easily to wear or even break. At this situation, it will be cause the

serious accident.

To sum up three points above, the no synchronous speed of the driving drum for

movable drum is the main reason of balance drum rotation. The secondary reason

is the different pull forces of lifting points on the two sides of movable beam

(which will make the balance drum to rotate a small angle). The movable beam

bottom or bucket wheel lay on the stockpile or ground will cause

In fact, the balance beam moves up and down several times there will be problem

that balance drum rotate at big angle. The gantry-type bucket wheel stacker &

reclaimer system is that balance drum of the movable beam runs permanently. If

the balance drum is not been adjusted immediately, the consequences will be

unthinkable.

3. The consequences of too big rotational angle of the balance drum of

movable beam for gantry-type bucket wheel stacker & reclaimer.

Too big rotational angle of balance drum (balance wheel) of movable beam for

gantry-type bucket wheel stacker & reclaimer will cause very serious

consequences, which are:

If the balance drum (or balance wheel) does not install the stop block, the

rotational angle of it would have not any limit. And the balance drum may turn

several laps.

If the balance drum to be installed with angle limiting block, suppose that the

limit is ± 45 degrees, it will hit the limit block after the movable beam being

lifted in several times. In some situation, a stop pin was designed on the

circular arc groove and to limit the balance drum rotation angle. If two balance

drums hit angle limiting block together, the tension forces of four ropes will

be not equal. Besides, due to the forces are uncertain, there are potential

security liabilities. The function of block or stop pin act as protection device

in case of the wire rope was broken.

If the rotational angle of the balance drum in one side is too big, even reach

to safety 3 laps, wire rope may been pulled out from the clamp, and the movable

beam will fall off. At the time, even if the rope was not been pulled out of

from the clamp, due to the rope been wound on drum reversely, the wire rope

maybe damaged and broken. In addition, due to the balance drum rotational angle

is too big, the ropes will been hurt by the steel structure. And steel ropes may

be broken leading to significant accidents.

4. To avoid the accidents of lifting system gantry of movable beam for

gantry-type bucket wheel stacker & reclaimer

We suggest, in the future, that design of lifting system of movable beam for

gantry-type bucket wheel stacker & reclaimer should adopt the automatic cable

balance system and the synchronization drive on drums. The balance drum that the

rotational angle can be cumulative should not been used.

The equipments has been designed and manufactured in the past should be equipped

with encoder, limit switch and other detection devices to monitor the balance

drum angle. The movable beam lifting system should adopt variable frequency

motor, and the driving motor can separately controlled when been lifting in one

side, in order to control the balance drum at a reasonable angle. In this case,

balance drum might rotate to a big angle position easily due to forces on the

two cables are unequally, operators and maintenance personnel should keep an eye

on the angle of balance drum.

Safety operating procedures should be obeyed strictly. The bottom of beam or

bucket wheel touched by the stockpile or ground is prohibited when lifting

movable beam the up and down.

In normal operation condition, the block of balance drum should not block the

rotation of drum unless the rope was broken. Otherwise, the balance drum will

not work due to steel ropes forces are not equal at the two sides.

It needs to have a comprehensive understanding of the principle of the movable

beam lifting system and the reasons of balance drum (balance wheel) rotation so

as to avoid the accidents during operation.

The design of movable beam lifting system exist a potential safety hazard when

the balance drums rotating at a big angle.

It needs to detect and adjust the rotational angle of balance drum immediately

when using the movable beam lifting system.

Excerpted from <Heavy Industrial & Hoisting Machinery>2017,first

About The Author

Li Yimin ;

Professor Engineer ;

Sex : Male ;

Graduated : DUT ->. Jan .1982;

Major : HOISTING AND CONVEYING MACHINERY ;

Metier: Designer For Bulk Machinery;

Main contribute for bulk machinery: He has embarked on design and

researsh Bulk Machinery for 34 years. Main contect include stacker

,reclaimer ,stacker / reclaimer , bridge type reclaimer , Blending

stacker ,Blending Reclaimer , gantry type reclaimer . He research the

main date for the bulk machinery especially.

He wrote many piece for the bulk machinery . some piece had released on

the journals in P . R . China , and had invented four item patents.

www.bulkcn.com 版权所有 屹立散料机械在线 大连重工2017-3-30

bulkcn@qq.com

bulktech@sohu.com

liyma@dhidcw.com

Tel: 0411-86852278