悬臂皮带运输机常见故障分析与处理(英文稿)

Common

Fault Analysis For Belt Conveyer

By

Li Yimin Aug 11.2008

Bulk-OnWeb www.bulkcn.com

Belt conveyers as continuous bulk material conveying machinery have been

widely used in the world, electric power plants, metallurgical industry and

foodstuff industry as well as in bulk material conveying machinery such as ship

loader and bucket-wheel stacker-reclaimer. In the purchase, design, manufacture,

erection and operation of this kind of equipment, some of new users are not

familiar with them. Common fault causes and their handling methods of this kind

of equipment are analyzed and described herein as a matter of experience in the

past years and from the point of view of users.

1. Handling of belt deviation

of belt conveyer: The belt deviation of belt conveyer during operation is the

most common fault. To handle this type of fault, emphasis should be placed on

the dimensional accuracy of erection and the routine maintenance. There are

several kinds of causes. The differential treatment should be made according

to the different causes.

1.1

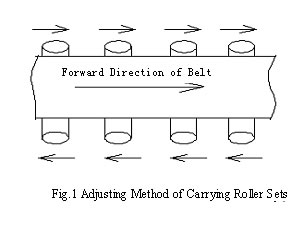

Adjustment of carrying roller set: If the belt of belt conveyer is

deviated in the middle of the whole belt conveyer, the position of carrying

roller set is adjusted. During the manufacture, the mounting holes on both sides

of carrying roller set are machined to slots for the convenience of adjustment.

For the specific adjusting methods, see Fig. 1. The specific method is that when

the belt is deviated from the side, that side of carrying roller set should be

moved forwards the direction of travel, or the other side moved backward the

direction of travel. If the belt is deviated from the upper direction as shown

in Fig. 1, the bottom position of carrying roller set should be moved to the

left side and the upper position of carrying roller set is moved to the right

side.

1.2 Installation of

self-aligning carrying roller set: There are many types of self-aligning

carrying roller sets such as intermediate rotating shaft type, four-link type

and edging roll type. The principle is that by utilizing blocking or rotating

the rollers in the direction of horizontal plane, the rollers are blocked by

rotating or the lateral thrust is produce to make the belt be automatically

aligned so as to attain the object of adjustment of belt deviation. It is

feasible, in general, to use this method when the whole length of belt of belt

conveyer is shorter or the belt conveyer is operated in the bidirection. The

causes are that the shorter belt conveyer is easier to be deviated and it is not

easily adjusted. Therefore, this method is not used for the longer belt

conveyers because use of self-aligning carrying roller sets can have certain

influence on the service life of belt.

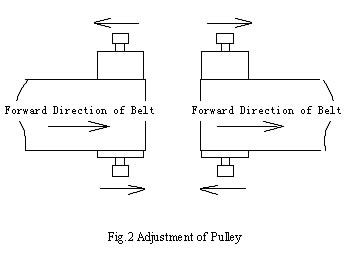

1.3 Adjustment of positions

of head roll and bend pulley: Adjustment of head roll and bend pulley is a key

link of adjustment of belt deviation. Since there are at least 2 to 5 pulleys

in one belt conveyer, the mounting position of all the pulleys must be perpendicular

to the central line along the length of belt conveyer. If the deviation is too

large, the belt deviation occurs of necessity. The adjusting method is similar

to that of carrying roller set. For head pulleys, if the belt is deviated from

the right side of pulley, the bearing block at the right side should be moved

forward and if the belt is deviated from the left side of pulley, the bearing

block at the right side should be moved forward. For corresponding pulleys,

the bearing block at the left side can be also moved backward or the bearing

block at the right side moved backward. The adjusting method of tail pulleys

is just opposite from that of head pulleys. For the adjusting method, see

Fig. 2. The pulleys are repeatedly

adjusted till the belt is adjusted to the expected position. It is preferable

to make the mounting position accurate before adjustment of head rolls or bend

pulleys.

1.4 Adjustment of belt tensioning device: Adjustment of belt tensioning device is a very important link

of adjustment of belt deviation of belt conveyer. Two bend pulleys on the top

of counterweighted tensioning device should be not only perpendicular to the

direction of the belt along length but also to the gravity vertical, i.e. it

is ensured that the shaft center line is horizontal. When the screw tensioning

device or hydraulic tensioning device is used, two bearing blocks of tensioning

pulley should be synchronously translated so as to ensure that the axial line

of pulley is perpendicular to the longitudinal direction of belt. The specific

adjusting method of belt deviation is similar to the adjusting method of pulleys.

1.5

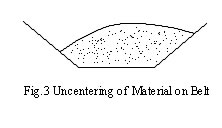

Influence of material receiving position at the transfer point on the belt

deviation: The material receiving position at the transfer point has a great

influence on the belt deviation, especially when the projection of two belt

conveyers in the horizontal plane. The relative height of the upper belt

conveyer and lower belt conveyer at the transfer point should be normally taken

into consideration. The lower the relative height the greater the horizontal

velocity component of material and also the greater the lateral impact on the

lower layer of belt. In addition, the material is difficult to center so as to

make the material at the cross section of belt be skew and finally lead to belt

deviation. If the material is deviated from the right side, the belt will be

deviated from the left side, vice versa. In the course of design, the relative

height of two belt conveyers is increased as practically as possible. The form

and dimension of the upper hopper and the lower hopper, chute etc. of bulk

material mobile conveying machinery which are limited by space should be more

carefully taken into consideration. In general, it is applicable for the width

of chute being about 2/3 of that of belt. In order to reduce or avoid the

belt from being deviated, the baffles can be increased to block the material and

change the falling direction and position of material. For the uncentering of

material on the belt, see Fig. 3.

1.6 Adjustment of belt deviation

of bi-directional belt conveyer: Adjustment of belt deviation of

bi-directional belt conveyer is relatively more difficult than that of

belt deviation of one-way belt conveyer. During the specific adjustment,

the adjustment should be done from one direction, and then from the

other. During adjusting, it must be carefully observed to the

relationship between the travel direction of belt and the tendency of

belt deviation. The adjustment should be done one by one. Firstly

emphasis should be placed on adjustment of head rolls and bend pulleys.

Secondly emphasis is placed on adjustment of the carrying rollers and

the material receiving point. In addition, it should be noted that the

load is uniformly distributed at the section of the belt along the

length when the belt is at the vulcanized joints. When the leading chain

is used for traction, the load at both sides should be distributed as

equally as possible.

2. Material spillage on belt conveyer: Material spillage on the belt conveyer is a general character.

The causes are embodied in several aspects. Therefore, emphasis is placed on

strengthening the routine maintenance.

2.1 Material spillage at

transfer point: Material spillage occurs mainly at the transfer points such

as material receiving hopper and chute. If serious overload occurs on the belt

conveyer, the rubber skirt plate of chute of belt conveyer can be damaged. Since

the steel plate of chute is far from the rubber skirt plate in the design, the

material will be flown out of the chute. The problem can be solved by controlling

the conveying capacity and strengthening the routine maintenance.

2.2 Material spillage

at the concave section of belt during hanging: The belt at the concave section

is floated when the radius of curvature is smaller. At this tome the belt in the

form of trough has been changed because the belt has been deviated from the

trough carrying roller set. In that case, the angle of trough becomes small so

as to make part of the material be split out. Therefore, the bigger radius of

curvature at the concave section is used as practically as possible in the

design in order to avoid the material spillage. If the concave section is

designed according to the section of transition without arc in the mechanical

traveling ship loader or stacker-reclaimer in order to shorten its tail car, the

material spillage may easily occur when there is less room for selection of belt

width.

2.3 Material spillage

during the belt deviation: The material spillage occurs during the belt

deviation because two edges of belt have changed in height during operation,

i.e. one edge is higher and the other is lower. The material is split out from

the lower edge. The handling method is to adjust the belt deviation.

3. Abnormal noise:

When the belt conveyer is operated, it could sound abnormally from its drive,

head roll, bend pulley or carrying roller set. The failure of equipment can be

determined according to the abnormal noise.

3.1 Noise occurs when

the carrying roller being seriously deviated: When the belt conveyer is

operated, the abnormal noise could be produced and accompanied by periodic

vibration, especially in the return rolls. The longer the roll and the heavier

the deadweight, the higher the noise. There are mainly two causes for noise: one

is that the wall thickness of seamless pipe made of carrying roller is

non-uniform so as to produce the greater centrifugal force and the other is that

during machining, the center of holes of bearing at both ends is greatly

deviated from the center of top circle so as to produce the greater centrifugal

force. The rolls can continue to use in case the bearings have not been damaged

and the noise is allowed to exist.

3.2 Noise occurs when two

shafts of coupling being not coaxial: The abnormal noise is produced from the

coupling between the high-speed shaft of motor in the drive and that of reducer

or from the coupling with brake wheel, it is also accompanied by the vibration

that is identical with the rotational frequency of motor. If the noise is produced,

the position of motor or reducer is adjusted in time in order to avoid the rupture

of input shaft of reducer.

3.3 Abnormal noise of bend

pulley and head roll: When the bend pulleys and head rolls are operated normally,

the noise is very low. If the abnormal noise is produced, the bearing, in general,

may be damaged. If the cackle is produced from the bearing block, the bearing

must be replaced.

4. Rupture of

shaft of reducer: The rupture of shaft of reducer generally occurs at the

high-speed shaft of reducer. The usual fault is that the first-stage shaft of

reducer is used as the high-speed shaft of vertical bevel gear shaft. There are

mainly two causes for shaft rupture as follows.

4.1 Inadequate design

strength of high-speed shaft of reducer: This fault, in general, occurs at the

shaft shoulder. Because the transient round angle exists at this place, it is

subjected to fatigue damage. If the round angle is too small, the rupture of

shaft of reducer can occur in the short time. After shaft rupture, the fracture

is generally flush. If this fault is found out, the reducer should be replaced

or the design of reducer should be modified.

4.2 High-speed shaft

being non-axial: When the high-speed shaft of motor is non-axial, the radial

load will be increased on the input shaft of reducer so as to increase the

bending moment on the shaft. If the shafts are operated in such a way for a long

time, the shaft rupture could occur. During installation and maintenance, the

position of shaft should be carefully adjusted in order to ensure that the two

shafts are aligned. In most cases, the rupture of motor shaft can not occur,

because the material used for motor shaft is #45 steel, the motor shaft is

thicker and has good stress concentration.

4.3 Rupture of shaft

in case two motors are used: The double-motor drive means that two reducers and

two motors are installed on one head roll. When there is less room for design or

selection of high-speed shaft of reducer, the shaft rupture easily occurs. In

the past years the hydraulic coupling was not used in the drive of belt

conveyer, so the failure easily occurred. The cause was that it was difficult to

ensure that the speeds were synchronous and the loads uniformly distributed. Now

the hydraulic couplings have been used in most of the belt conveyers, so the

shaft rupture does not frequently occur, but it should be noted that the

hydraulic coupling can not be filled with excess quantity of oil during

operation so as to make it have an effect on limitation of moment of force and

increase the service life of hydraulic coupling.

5. Shorter service life of

belt: The service life of belt and the service modes are related

to the quality of belt. It should be ensured that the cleaners are operated

reliably and in good order when the belt is operated. There is not any material

on the return belt. If the above can not be guaranteed, the material on the

return belt will enters into the head roll or the bend pulley along with the

return belt. The belt will be damaged due to the material on the surface of

belt, resulting in damage of the vulcanized rubber layer on the surface of pulley,

breach of the belt and decrease of the service life of belt. The manufacturing

quality of belt is the problem the users relatively give attention to. After

the selection of a model of belt, its manufacturing quality should be also taken

into consideration. The belts can be inspected by the national specialized institution

of quality determination. The appearance inspection is carried out conventionally

to see whether the crazing and aging exist and the resting period is over long

after manufacture. One of the above occurs, the belts should not be purchased.

The fissured belt to be initially found will be, in general, damaged in a short

time.

6. Influence of radius of

curvature at the convex-concave section of belt on belt conveyer

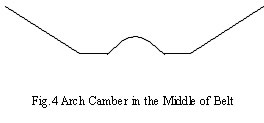

6.1 Arch camber at the convex section of belt in the

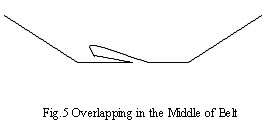

middle of cross section: The arch camber often occurs at the convex

section in the middle of cross section and the belt will be pleated, see Fig. 4.

After the overlapped

belt enters into the bend

pulley or head roll, the extent of damage of belt aggravated. The main causes

for arch camber and overlapping are that the difference between the values of

tensile force in a unit of length at the cross section of belt in the middle and

on the outside is oversized so that the belt is slid into the middle to form the

arch camber or overlapping. The magnitude of difference value of tensile force

in a unit of length is related to the radius of curvature at the convex section

and the trough angle of carrying roller. The bigger the trough angle, the

smaller the radius of curvature at the convex section and the severer the arch

camber and overlapping. When the trough angle of belt conveyer is equal to and

more than 40 degrees, the arch camber and overlapping can occur even at the

transition section of trough angle of head or tail roll which is run at the

straight section. At this time the trough angle should be reduced or the length

of transition section increased so as to make the trough angle of belt be

transited. For the belt conveyer at the convex section, the radius of curvature

at the convex section should be increased as practically as possible and the

trough angle of roll reduced in the condition that the conveying capacity is

met.

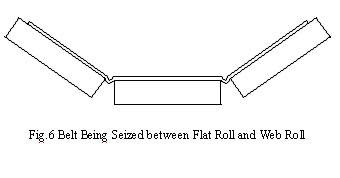

6.2 The belt at the

convex section being seized between flat roll and web roll: The belt being

seized between the flat roll and the web roll in the carrying roller set may

generally occur in the bulk material mobile

conveying machinery such as

ship loader and stacker-reclaimer. The belt seizure may easily occur when the

cantilever at the root position of cantilever beam of such equipment is pitched

downward. At this time it corresponds to the convex section occurring on the

belt. The size required for the radius of curvature at the convex transition

section can not be easily met because it is limited by the size of geometric

position. The belt being seized between the flat roll and the web roll in the

carrying roller set can occur only when the belt at the root of cantilever is

passed through one or two carrying roller sets to form the convex section. The

method of resolution is that the convex section formed by the original one or

two carrying roller sets is changed to that formed by four or five carrying

roller sets. For example, the belt conveyer is horizontally arrange at its rear,

the cantilever is pitched downward at the angle of 12 degrees at its fore and

the convex section is changed at the angle of 12 degrees. If five carrying

roller sets are used to transit the angle change in this place, the belt is just

buckled six times to attain the object of pitching downward at the angle of 12

degrees. The belt is buckled once at the angle of 2 degrees. After modification,

the belt being seized between the flat roll and the web roll in the carrying

roller set can not occur no longer. The design of four-link lever or follow-up

frame can be used for the base of roller carrier in the transition place which

position of angle is changed.

6.3 Bouncing and deflection

of belt by the wind at the concave section when starting:

If there is not any material on the belt when the belt conveyer is started,

the belt will be bounced at the concave section and displaced by the wind in

windy weather. Therefore, it is preferable that the pressure rollers are provided

at the concave section to avoid the belt from being bounced or displaced by

the wind.

7. Slipping of belt

7.1 Slipping of belt of belt

conveyer with counterweighed tensioning device: When the belt is slid in the

belt conveyer with counterweighted tensioning device, it can be solved by adding

the balance weights till the belt can not be slid. However, the balance weights

should not be excessive in order to avoid the belt from being subjected to

unnecessary oversized tensile force, thus resulting in decrease of the service

life of belt.

7.2 Slipping of belt of belt

conveyer with screw tensioning device or hydraulic tensioning device: The tensioning travel can be adjusted to increase the tensile

force when the belt is slid in the belt conveyer with screw tensioning device

or hydraulic tensioning device. At this time, however, a section of the belt

can be cut out for re sulfurzation when the tensioning travel is not enough

or the belt is permanently deformed.

Brief summary: The belt conveyers are

general-purpose mechanical equipment. They have been operated by the users for

many years. However, the maintenance of belt conveyers must be done at regular

intervals. Because of limitation of the length of a piece of writing, it is

difficult indeed to include all contents in one article. The experience with

operation and maintenance of belt conveyer can be gradually accumulated through

routine work. We hope that this text will be helpful for the users of belt conveyer.

(未经著作权人和本站的书面许可不可转载和使用本稿件)

返回首页

返回散料机械技术论文